After completing my first led projector mod i was commissioned to do another one, with an even more powerful led this time

This time around i modified a phillips hopper sv10, which had a burned out polarizer i replaced earlier in the year. Thinking the interface would be identical because of the same manufacturer and they were similar models built around the wrong time, obviously i was wrong.

Instead of a heart beat signal and active low feedback the control signal was a simple active high pulse, feedback required a constant 5 volt line to be pulled down. Using my scope wasn't very helpful as i was expecting a squarewave signal (really need a second probe while im at it) but my new logic probe made quick sense of it.

This time around i used a 50 watt led, 32 - 36 volt power supply, reflector and a pack of credit card frenel lenses to play with.

I mounted the led exactly the same way as before: i removed the uhp bulb cage and hacked off a piece that screwed onto the rest of the assembly

Drilled small pilot holes for mounting the led

Then drilled and tapped for 6 - 32 screws

The plastic piece i hacked off was bolted to the top to mount the led at the perfect position.

A bit of thermal silicone to hold the led in place and give better thermal conductivity

And finally screw into place. My control board is nearly identical to my previous version, with the exception of the extra transistor used to pull the 5 volt line to ground

Alot smaller and cleaner than my last version, also i found a place to pull 5 volts off the power supply removing the need for its own supply.

Im still in the process of testing different lenses but the credit card frenel lenses seem to do the trick... im a bit concerned that it might sag during prololged operation since it is just a piece of cheap plastic.

Time will tell i suppose, perhaps adding a fan to blow over the front of the led is a solution.

So far it is quite a bit brighter than the 25 watt led i previously used, but it does get much hotter and i will need to attach a fan directly to the heatsink i used, seems to get close to 45c right now but that is with the case open

I am unable to take proper pictures of the projector in action, everything i take with it is way to dim to make out most of the projected image

Nearing the completion of the project i had an accident: i dropped a screw while reassembling the projector which just had to hit a 400v 150uf capacitor which discharged onto the control interface cable and destroyed it... The projector survived, could turn on and off and would display fine through vga but i could not change any settings or inputs making the projector quite useless.

I guess its off ward to the next one, an eiko EIP-2500 DLP projector... i plan on taking the led system from the now failed mod and installing it into the dlp projector

Friday, October 7, 2011

Tuesday, August 30, 2011

Camper Trailer LED Conversion

My parents recently got a camper, which was a huge step up from a tent and considerably better than the cramped tent trailer from my childhood. One issue for myself was the lighting, almost all campers still use 12 volt incandescent bulbs, they bathe everything in a terrible orange glow and either are too dim or have a pathetic lamp life of less than 200 hours.

This simply would not do, my parents did not use the campers lights simply because the damn lights got too hot and melted the polycarbonate dome causing it to sag. They used too high a wattage bulbs but the ones that were rated for the fixture you could not even read by.

A quick bit of searching and i found appropriately sized cool white 108 lumen 12 volt led panels, they took forever to arrive but a a price of 2 dollars apiece on a bulk order in november i would not expect them to arrive any time soon anyways.

Considering the life expectancy of leds drops quite a bit at higher temperatures and that the panel would be enclosed i decided to add a heatsink. Mounting the lights ended up being easier, i simply broke the the glass and soldered the panel directly onto the wire that held the filament. The result was alot sturdier than i thought it would be and required no modification to the fixture. The heatsink was attached using some silicone thermal glue.

The result was impressive, the light given off was much better than the original bulbs. A much better brighter white light. The leds get around 35c after being left on for an hour... considering that they will not be under continuous use and will only be used seasonally i would expect them to last the life of the camper.

A few of the led panels exhibit problems when they heat up

Saturday, August 13, 2011

Crazy Analog Memory

Sadly i recently had to dismember my ancient Tektronics Analog scope, it happened to be manufactured in 1967 and was the first analog storage scope commercially available from Tektronics

Channel one was toast and the tube was quite slow but it did its job for a year after i pulled it from a dumpster along with a few hundred pounds of industrial equipment.

It will be missed, although it has been replaced with a much faster and considerably smaller analog scope and a function generator. I stripped it for parts and scrap aluminum simply because i am moving in a few weeks and could not find a home for it. Lots of dials, switches, tubes, germanium diodes and whatnot inside but there was something that made absolutely no sense, a heavily shielded cable about 2 meters long stuffed inside of a shielded box labeled danger high voltage. It has 2 enameled wires inside tightly wound around a plastic core, i worked out that each wire had to be several kilometers long.

After some pondering i concluded that this had to be what was used for the storage component of the scope. It simply used the length of the cable to provide sufficient delay followed by amplifying the signal and feeding it back into the other end, an analog version of delay line memory.

Channel one was toast and the tube was quite slow but it did its job for a year after i pulled it from a dumpster along with a few hundred pounds of industrial equipment.

It will be missed, although it has been replaced with a much faster and considerably smaller analog scope and a function generator. I stripped it for parts and scrap aluminum simply because i am moving in a few weeks and could not find a home for it. Lots of dials, switches, tubes, germanium diodes and whatnot inside but there was something that made absolutely no sense, a heavily shielded cable about 2 meters long stuffed inside of a shielded box labeled danger high voltage. It has 2 enameled wires inside tightly wound around a plastic core, i worked out that each wire had to be several kilometers long.

After some pondering i concluded that this had to be what was used for the storage component of the scope. It simply used the length of the cable to provide sufficient delay followed by amplifying the signal and feeding it back into the other end, an analog version of delay line memory.

Friday, August 12, 2011

POV Clock

I found an interesting persistence of vision clock for a few dollars at a local thrift shop

Its a simple 8 led array on a thin piece of pcb held up by a spring with a magnet, a large coil pulls the array forward and the spring does the rest of the work, the base is a nice polished piece of aluminum... when running there is a surprising amount of rocking force so a heavy base makes sense

It is controlled by an old Atmel AT87F52 microcontroller, an LM339 comparator for the break beam sensor (i think), 74hct244 to drive the leds and a 2k eeprom to store custom messages. A ksp2907 transistor drives the coil. I would like to replace the mcu with something more modern, with a proper RTC and communication, adding RSS feed capabilities and maybe changing the led color

Its a simple 8 led array on a thin piece of pcb held up by a spring with a magnet, a large coil pulls the array forward and the spring does the rest of the work, the base is a nice polished piece of aluminum... when running there is a surprising amount of rocking force so a heavy base makes sense

Other than showing the time there are a number of annoying messages, looks to be an easy thing to hack

Wednesday, August 10, 2011

Solder Pot

I recently acquired a cheap 200 watt solder pot to speed up disassembling old electronics, it took 600 grams of solder to fill... its quite deep, i might consider stretching the amount of solder using steel ball bearings if if have to refill it.

The element is regulated by a simple triac circuit, there is nothing to stop it from overheating and no real way to precisely control the temperature, also the base is small and the entire thing is top heavy when filled. After the solder is completely filled i turn it down almost as it can get, anything higher causes the solder to rapidly oxidize.

After an hour of messing around with it im pretty happy with the results, and i have a good future project of building a digital temperature control and a larger sturdier base, the electronics are currently right beside the element and will most definitely fail rather quickly if i let the thing overheat.

Monday, April 4, 2011

Projector Update

I finally finished the project, i am quite happy with the results and now have plans to improve the concept with brighter light sources. Im thinking either 12v hid automotive lamps or higher power leds.

Control Board

The control board consists of a pic12f675, a relay, npn transistor, a protection diode for the relay and some resistors... nothing particularly special.

Code

#include <htc.h>

#define _XTAL_FREQ 4000000

__CONFIG(MCLREN & UNPROTECT & BORDIS & WDTDIS & PWRTEN & INTIO);

void main()

{

TRISIO = 0b111100;

ANSEL = 0;

while(1)

{

GPIO = 0b000010;

// wait for power on signal, 5 seconds long

for(int x = 0; x < 2000; x++)

{

__delay_ms(1);

if(GPIO2 == 0) x = 0;

}

GPIO = 0b000001;

// wait for ~1 ms pulses to stop, after 100 ms of nothing turn off

for(int x = 0; x < 100; x++)

{

__delay_ms(1);

if(GPIO2) x = 0;

}

}

}

High Power Led

The led and power supply came in, i wasn't expecting how bright these things would be. Everything came together perfectly somehow...

I mounted the led onto an aluminum heatsink with some screws and some thermal silicone adhesive, to mount the whole thing into the projector i removed the top part of the bulb cage and cut out the section that screwed onto the projector. I happened to have a collimator lens i salvaged from another projector that fit on top of the reflector, with the reflector and lens siliconed down it was ready to install. A note of warning, the power leds tend to have a silicone lens injected over them which is quite fragile and easily peeled off. I almost had this happen when my reflector came off and the silicone i used bonded to the lens!

Its not quite as bright as the uhp bulb but that could easily be fixed with an led with a higher output

Power Supply

The power supply was based on an st micro TSM101I voltage amperage controller, i used a simple hack using a 100k resistor and a 10k potentiometer to fine tune the amperage supply so the led isnt over driven and die prematurely.

At 1.7 amps the heatsink provided (if you can call a thin piece of aluminum one) got quite warm, i found an aluminum heatsink of the perfect dimensions. I siliconed the heatsink down so it wouldn't shift and mounted the power supply using silicone thermal adhesive

Testing

Surprisingly everything worked perfectly, the projector turned on and off just as it would before. A slight disappointment was the fact that the led was not as bright as i hoped it would be, it ended up producing an image about as half as bright as it originally did. This is with the brightness of the projector turned all the way up.

The projected image is a bit brighter and has proper color, my camera sucks for these types of situation.

Conclusion

For about 50 dollars (including consumables) i retrofitted the projector in about 2 hours of solid work and 4 or 5 hours of figuring out the basics of pic micro controllers. For a bit more money a much brighter led can he had that would make this more worthwhile. Considering how much longer an led will last compared to the ~2000 of a uhp lamp and the power savings. Power loss from the conversion taken into account powering the led comes to about 30 watts, one quarter of the power consumed by original bulb.

Control Board

The control board consists of a pic12f675, a relay, npn transistor, a protection diode for the relay and some resistors... nothing particularly special.

Code

#include <htc.h>

#define _XTAL_FREQ 4000000

__CONFIG(MCLREN & UNPROTECT & BORDIS & WDTDIS & PWRTEN & INTIO);

void main()

{

TRISIO = 0b111100;

ANSEL = 0;

while(1)

{

GPIO = 0b000010;

// wait for power on signal, 5 seconds long

for(int x = 0; x < 2000; x++)

{

__delay_ms(1);

if(GPIO2 == 0) x = 0;

}

GPIO = 0b000001;

// wait for ~1 ms pulses to stop, after 100 ms of nothing turn off

for(int x = 0; x < 100; x++)

{

__delay_ms(1);

if(GPIO2) x = 0;

}

}

}

High Power Led

The led and power supply came in, i wasn't expecting how bright these things would be. Everything came together perfectly somehow...

I mounted the led onto an aluminum heatsink with some screws and some thermal silicone adhesive, to mount the whole thing into the projector i removed the top part of the bulb cage and cut out the section that screwed onto the projector. I happened to have a collimator lens i salvaged from another projector that fit on top of the reflector, with the reflector and lens siliconed down it was ready to install. A note of warning, the power leds tend to have a silicone lens injected over them which is quite fragile and easily peeled off. I almost had this happen when my reflector came off and the silicone i used bonded to the lens!

Its not quite as bright as the uhp bulb but that could easily be fixed with an led with a higher output

Power Supply

The power supply was based on an st micro TSM101I voltage amperage controller, i used a simple hack using a 100k resistor and a 10k potentiometer to fine tune the amperage supply so the led isnt over driven and die prematurely.

At 1.7 amps the heatsink provided (if you can call a thin piece of aluminum one) got quite warm, i found an aluminum heatsink of the perfect dimensions. I siliconed the heatsink down so it wouldn't shift and mounted the power supply using silicone thermal adhesive

Testing

Surprisingly everything worked perfectly, the projector turned on and off just as it would before. A slight disappointment was the fact that the led was not as bright as i hoped it would be, it ended up producing an image about as half as bright as it originally did. This is with the brightness of the projector turned all the way up.

The projected image is a bit brighter and has proper color, my camera sucks for these types of situation.

Conclusion

For about 50 dollars (including consumables) i retrofitted the projector in about 2 hours of solid work and 4 or 5 hours of figuring out the basics of pic micro controllers. For a bit more money a much brighter led can he had that would make this more worthwhile. Considering how much longer an led will last compared to the ~2000 of a uhp lamp and the power savings. Power loss from the conversion taken into account powering the led comes to about 30 watts, one quarter of the power consumed by original bulb.

Monday, March 7, 2011

Projector LED Mod

I happen to have a stack of old Phillips 3 lcd projectors, the ones i repaired work great... but only until the uhp bulbs burn out and at a hundered bucks a pop minimum to replace, probably more considering the age of the projectors its really not worth the price

Now if i were to replace the uhp bulb and high voltage board with a high power led for a fraction of the price that would be worthwhile, especially considering how much longer the led will last compared to the 2000 or so hours from a uhp lamp.

Some quick poking around the insides of any of the projectors resulted in a 3 wire connection from the high voltage supply to the control board. Probing with a dmm showed 5 volt signals, further probing with an oscilloscope showed that the control board pulses a high signal to start the hv board which gives a constant low while the bulb is running. While the bulb is active the control board gives a continuous pulsed signal, when that signal stops the bulb is turned off.

Pretty straightforward so far, 40 $ worth of parts are on their way and i have already figured out how i am going to implement control using a pic micro controller.

Now if i were to replace the uhp bulb and high voltage board with a high power led for a fraction of the price that would be worthwhile, especially considering how much longer the led will last compared to the 2000 or so hours from a uhp lamp.

Some quick poking around the insides of any of the projectors resulted in a 3 wire connection from the high voltage supply to the control board. Probing with a dmm showed 5 volt signals, further probing with an oscilloscope showed that the control board pulses a high signal to start the hv board which gives a constant low while the bulb is running. While the bulb is active the control board gives a continuous pulsed signal, when that signal stops the bulb is turned off.

Pretty straightforward so far, 40 $ worth of parts are on their way and i have already figured out how i am going to implement control using a pic micro controller.

Monday, February 21, 2011

555 Timer Contest Entry: EL Inverter

This project actually started before the contest was announced, its purpose is to provide a simple tunable circuit to drive EL components. Most drivers you can fins will only provide enough power to light a few feet of EL wire and drive at a static frequency. I wanted to observe the color shift that occurs when driving at higher frequencies.

The circuit is a simple 555 timer in astable mode with a 10k potentiometer to adjust the working frequency from around 150 to 3000 hertz. The output is used to switch a tip122 power transistor which sinks a transformer that produce close to 100 volts ac. Please note that many audio transformers are potted with a low melting point wax and can get warm enough to leak and fill the holes of your breadboard!

The circuit works perfectly as expected, although since the duty cycle is not constant the voltage does increase a fair bit as the operating frequency increases.

A nice color shift from aquamarine to blue is observed when adjusting the frequency above 2000 hertz.

The circuit is a simple 555 timer in astable mode with a 10k potentiometer to adjust the working frequency from around 150 to 3000 hertz. The output is used to switch a tip122 power transistor which sinks a transformer that produce close to 100 volts ac. Please note that many audio transformers are potted with a low melting point wax and can get warm enough to leak and fill the holes of your breadboard!

The only difference between the circuit i designed and what i built is a 10 ohm power resistor between the emitter pin of the power transistor and ground to prevent it from sinking too much current and overheating.

The transformer im using is an old 5v wall wart transformer being run backwards.

The circuit works perfectly as expected, although since the duty cycle is not constant the voltage does increase a fair bit as the operating frequency increases.

A nice color shift from aquamarine to blue is observed when adjusting the frequency above 2000 hertz.

Wednesday, February 16, 2011

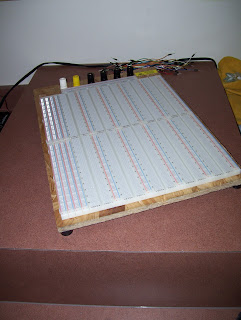

Giant Breadboard

I always seem to quickly run out of breadboard space, even with simple circuits...

With ten 6.5" * 2.125" breadboards anything requiring more space might as well have its own custom pcb

With ten 6.5" * 2.125" breadboards anything requiring more space might as well have its own custom pcb

Subscribe to:

Posts (Atom)