Quite a few years ago I did a digitization project for a number of 8mm reel to reel home movies. The setup was pretty simple: an old brownie projector, a large screen and a Hi-8 camera. The result was adequate for the time, but required quite a bit post processing to clean up. Film can run at 16 to 18 ish frames a second while the camera ran at 24 static. The color was off, everything was either too dim or over exposed. Additionally when a frame is advanced it is blocked off momentarily to prevent blur during pull-down, this is made more periodic to make it less noticeable to the human eye but causes serious issues with video cameras recording at a faster rate. At the time it took me 6 months to process mpeg-2 video, having to clean up frames one by one at times. This was around 2005 and my phone now is several times more powerful than my computer was then, the results were pretty good considering the resources at hand.

Sometime afterwards I acquired an old 8/Super 8 projector and decided to take another crack at this, having squired 50 or so more reels that needed digitizing. The first step was to gut the entire projector of its electrical, fabricate a new takeup reel and make modifications to the film gate.

Gutting the projector was the easy part, other than the lamp housing and the transformer there was little else in this thing.

Regarding the film gate, a sizeable portion of the film is not seen on the projection. The image is cropped down so the perforations are not visible along with the intermediate region between frames. Since i want to capture as much of the film as possible I enlarged the gate as much as possible for both Super-8 and Regular-8 Film

The original take up reel was missing so I ended up adapting one from an old reel to reel magnetic tape player, it fits and the wobbly thing on the end that allows the reel to hold tension in one direction while allowing the projector to go in reverse works.

I decided fairly early on to use an arduino for the brains of the projector. There isn't much requirements wise: control the brightness of the bulb, advance to the next frame, load film so i picked a fairly cheap easy to program Arduino and a motor control shield and called it a day.

The lamp was a bit of a tight fit, i needed sufficient material to act as a heat sink while allowing for enough room for a reflector without it touching the claw down mechanism. I used a 5300K CREE X-RE led module in a small drop in module cut down to size bolted onto a 1/4 inch thick piece of aluminium that i managed to cut down and make fit.

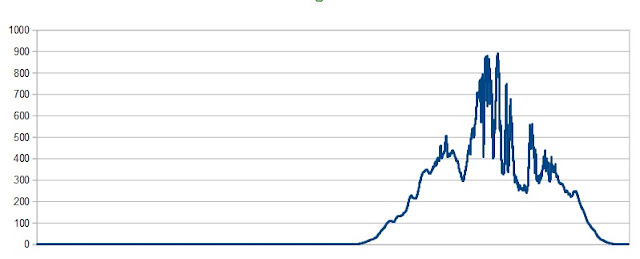

In order to drive the LED properly I threw together a simple NPN sink drive circuit with a 10 ohm 2 watt resistor in series. Generally driving a power LED with a resistor for current limiting is a bad idea but in this case the load is so small the chance of overheating and the resistor allowing too much current is not a concern.

In order to advance by a single frame I needed a way of knowing when the claw mechanism finished pulling down the next frame, fortunately them main drive pulley controls this directly via a notch on the side that pushes down a little spring arm. So using a black mark on the drive wheel and a photo reflective sensor this is easily achieved.

The original switch control has a position for threading the film that moves some channels to get the film to bend in the right shape. Back when I did this I was lazy and didn't probe out the original switch so I ended up mounting a mechanical switch where I could detect the mechanical position instead.

For the purpose of threading I installed a photo interrupt switch to detect the leader, since its more or less useless for detecting the film itself since it barely absorbs infrared light.

Most of the hardware modifications ended up being straightforward however the camera took quite a bit time to get right. I ended up choosing a logitech c600 webcam for the imaging sensor, at the time it was the highest resolution 4:3 webcam available for end users. It took longer to find appropriate lenses that had a short enough focal point while being adjustable. I ended up going with a surplus machine vision 22mm lens that screwed into a brass bushing. The dimensions were perfect for it so slide into the mount that held the original projection lens. I glued the webcams lens mount to some scrap plastic that allowed the sensor to be centred in the bushing. The lens had a gear machined into it i ground off to make it fit flush to the projector.

I added a small heatsink to the lcd to try and keep it cool in an attempt to keep it cooler to reduce noise. No clue if it will help but doesn't hurt. The power supply is just an old atx psu i wired up for 12v and 3.3v power nothing special.